Management Philosophy

-

Contribution to the society

We advance our operations for our customers by staring at the society

where the customers belong from the best total balance point of view.

We deeply and thoroughly consider what manufacturing should be and contribute to the society through manufacturing. -

Explore opportunities out of changes

We consider changes of time as chance, and work on such changes.

We step forward with courage, diligently work on changes and aim at becoming a frontier to create a new value. -

Autonomy and Growth

Growth of an organization (team) is sustained by individual growth of its members.

We urge our people to grow to be truly autonomous individuals by brushing up knowledge,

skill and human power to be real professional. -

Collaboration

We enlarge our business possibility and nurture flexible corporate culture through collaboration.

We strengthen ourselves together with others by opening our minds toward outside,

connecting ourselves to various fields and regions and sharing the values. -

Management through team

We consolidate all our forces into a team to generate synergy there.

We form an organization with the spirit of respecting each other, sharing mutual wisdom,

enhancing our vision together and open-minded with each other.

Corporate Information

-

Name of the companyKONNO CORPORATION

-

President

and CEOHiroyoshi Konno

-

Year of foundationApril 1961

-

Year of incorporationOctober 1969

-

Paid in

capitalYen 30,200,000

-

Details

of our

businessesHydraulic Equipment BusinessDesign and manufacture EAGLE toe-jack and related hydraulic equipment.

We are "the best partner to improve lifting, moving and position-adjustment" of heavy and expensive loads.Sheet Metal Processing BusinessProcess and provide stainless devices and fixtures to be used in clean environments on an order-made service basis. We are the best partner to productize R&D equipment and devices.Engineering & Service BusinessIndividually manufacture special devices and jigs to be used for R&D in the various fields (laboratory, engineering, ocean development, agriculture, welfare and so forth) .Welfare Equipment BusinessDevelop, manufacture and sell welfare equipment etc.

-

Business LocationsHeadquarters/

Tokyo Plant1-22-4 Ohgi, Adachi-ku, Tokyo 123-0873, JapanOsaka Sales Office3-4-17 Nagata, Joto-ku, Osaka-shi, Osaka 536-0022, JapanFukushima Plant154-5 Aza Kitahara, Oaza Fukuda, Shinchi-cho, Soma-gun, Fukushima Prefecture 979-2708, Japan

-

Corporate OfficersPresident and CEO

Managing Officer

Managing Officer

Hiroyoshi KONNO

Kazuhiro SHIRASU (Managing officer in charge of Engineering and Production )

Michiyo KONNO ( Managing officer in charge of General Affairs )

-

Number of Employees36 as of January 2017

Corporate History

-

The First Period

-

In 1961

Mr. Yoshimi Konno, the founder and the first president started his business in Kita-ku, Tokyo as an individual business owner. He was engaged in manufacturing devices for medical, physical and chemical requirements.

He and his wife were the only employees at that time.

He and his wife were the only employees at that time.

- In 1969

Konno Corporation was established as Limited Liability Company.

※Click on the image to view

※Click on the image to view

enlarged / explanation - 1970〜75

It expanded its business for stainless sheet metal processing by introducing sheet metal facilities on a step by step basis.

It began repair business for carrying equipment.

It began the development of hydraulic toe-jack. It acquired six Utility Models and two Registrations of Design related to the toe-jack. EAGLE jacks were given birth through the collaboration with their users and a large hydraulic jack manufacturer.EAGLE jacks were given birth through the collaboration with their users and a large hydraulic jack manufacturer.

EAGLE jacks were given birth through the collaboration with their users and a large hydraulic jack manufacturer.EAGLE jacks were given birth through the collaboration with their users and a large hydraulic jack manufacturer.

- In 1976

It began to sell EAGLE marked toe-jacks.

- In 1980

It received an order for the enclosure of physical and chemical equipment and experimental devices.

It enlarged its business in a favorable pace by receiving the contract to produce muffler etc. for special vehicle.The company explored the possibility of the mass production of its sheet metal processing. - In 1981

The company changed its registration to Joint Stock Company.

It established its Fukushima Plant in Soma-gun of Fukushima Prefecture, dedicated for its toe-jack production, and began its operation.

-

The Second Period

- 1984~1990

The company expanded the EAGLE lineups by developing the derivative products of its hydraulic jacks and of heavy machinery moving equipment so as to meet the users' demand voices.

- In 1995

Hanshin-Awaji Great Earthquake occurred.

Our toe-jacks were recognized as disaster relief equipment through the rescue and restoration operations of this disaster. After the disaster, the Tokyo Fire Department purchased 1,000 of our toe-jacks and since then, those jacks were adopted as a sort of standard disaster relief equipment by prefectural governments, firefighting departments and the Self Defense Forces.

Our toe-jacks were recognized as disaster relief equipment through the rescue and restoration operations of this disaster. After the disaster, the Tokyo Fire Department purchased 1,000 of our toe-jacks and since then, those jacks were adopted as a sort of standard disaster relief equipment by prefectural governments, firefighting departments and the Self Defense Forces.

- 1996〜1998

The company made it clear to shift the operational direction of its Sheet Metal Division from mass production oriented to single custom-made oriented, and began to work on the succession of its craftsmen's technology and skill. - In 1999

Its Fukushima Plant achieved a small lot production system as the result of its first production innovation activity.

This production system enabled the plant to produce its products for the quantity that its customers just need no matter how small it is and to deliver them on a timely manner, namely the "small production lot", "many types of products", and "short lead time" production was explored in this period.

This production system enabled the plant to produce its products for the quantity that its customers just need no matter how small it is and to deliver them on a timely manner, namely the "small production lot", "many types of products", and "short lead time" production was explored in this period.

-

The Third Period

- In 2001

The new company logo was defined. And the catchphrase "Shape the wants" was newly released.

- In 2002

The IT infrastructure was established to connect the Tokyo, Fukushima and Osaka operations. By introducing a groupware to share information internally, the intra-business collaboration was strengthened. - In 2003

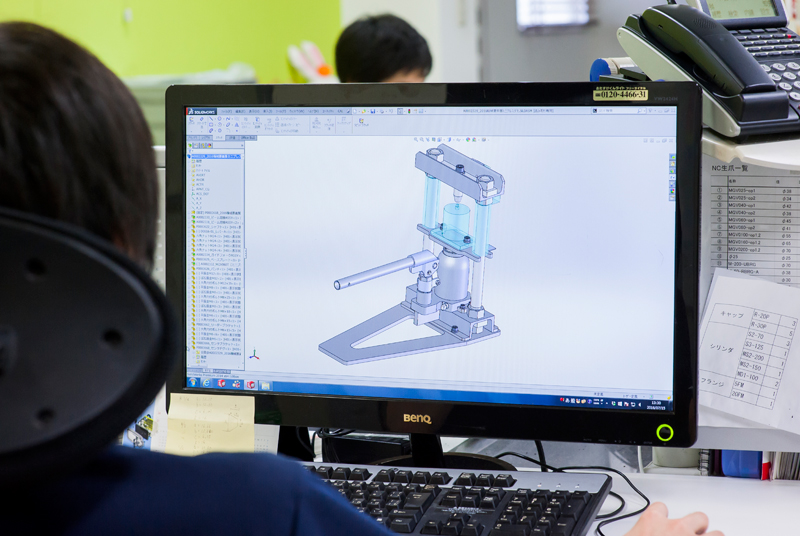

The company's product design capability was strengthened by the introduction of the 3D CAD Solidworks and by utilizing the structure analytical software.

The founder Mr. Yoshimi Konno assumed the corporate chairman's position and Mr. Hiroyoshi Konno succeeded his position as the second president. - In 2004

The 2nd production innovation activity started.

The EAGLE brand logo design was renewed.

- In 2005

The company started the development of the detachable and manual driving control device "SWORD" in collaboration with a welfare equipment planning and sales company. - In 2006

The company dispatched its young employees to the Tokyo Metropolitan Government sponsored master-hand cram school. It built several personal systems to grow human resources.

It increased its paid-in capital to Yen 30,200,000 by getting an investment from Tokyo Small and Medium Business Investment & Consultation Corporation. - In 2007

The company conducted "Training to strengthen manufacturing strength" by utilizing the order-made training system of Tokyo Metropolitan Small and Medium Enterprise Support Center. - In 2008

The new Fukushima Plant was built.

The Eagle Technical Center (Hydraulic Jack Laboratory) was established. In this year, the strong headwind so-called "Lehman Shock" blew in Japan and the company suffered from the large decrease of orders. President Konno declared "We should overcome it with the united forces of all of us", and instead of laying off any employees, the company focused on Kaizen activity, employees training and R&D by using the time left due to the business shrinkage.

In this year, the strong headwind so-called "Lehman Shock" blew in Japan and the company suffered from the large decrease of orders. President Konno declared "We should overcome it with the united forces of all of us", and instead of laying off any employees, the company focused on Kaizen activity, employees training and R&D by using the time left due to the business shrinkage.

- In 2009

The company began to sell the detachable and manual driving control device (SWORD).

- In 2010

The company began "Business Process Visualization Project" by incorporating the business process reengineering method that uses the business process reference model. Simultaneously, it worked on "IT Kaizen Activity" by receiving cooperation from Hosei University's Design Engineering Department. - In 2011

The Great East Japan Earthquake Afflicted the Fukushima Plant

The Fukushima factory located in Shinchi Town, Fukushima Prefecture, was struck by the huge diseaster. While the coastal area of the town was hit by the tremendous damage caused by the tsunami and there was worry about the impact of the nuclear accident, our employees worked together recovery. We resumed operation in two weeks and tried to supply the jacks highly required from the disaster-stricken area .

The Fukushima factory located in Shinchi Town, Fukushima Prefecture, was struck by the huge diseaster. While the coastal area of the town was hit by the tremendous damage caused by the tsunami and there was worry about the impact of the nuclear accident, our employees worked together recovery. We resumed operation in two weeks and tried to supply the jacks highly required from the disaster-stricken area .

-

The Fourth Period

- In 2015

The company internally developed the new production management and price estimate management system for its Sheet Metal Business and started its operation. - In 2016

President Konno assumed Director of General Incorporated Association Industrial Value-chain Initiative.

The company was awarded JICA's SME ODA project feasibility study contract.

Corporates alliance "Tokyo Backstreet Factories Manufacturing Network" project started.

History of awards

-

History of awards

- In 2011

Nominated by Tokyo Metropolitan Government as "Shining technology and illuminating enterprise"

- In 2012

Certified by the Ministry of Economy, Trade and Industry as SME IT based Management Award's model company

Awarded the highest prize of "Human Resources Growing Awards" by Tokyo Metropolitan Government - In 2014

Nominated by Japan Vocational Ability Development Association as "Chairman's Encouragement Company with regard to carrier development support companies"。 - In 2016

Chosen by the Ministry of Economy, Trade and Industry as "Top 100 SME of 2016 for proactive use of IT for corporate management"

Given the highest award for IVI's "Connected Manufacturing Award of 2016"

Certified by the Ministry of Economy, Trade and Industry as "Smart Factory Demonstration Business"。

Awarded "Distinguished Service Prize" by Tokyo Metropolitan Small and Medium Enterprise Support Center